Share article:

Despite what you see at first glance, no two production lines are the same. The products they run, how they are set out, people on the line, run length, maintenance and management will all play a key part in how they operate.

A respected sage like person once told me “you can’t see it sat on your arse”. Or more simply, if you want to assess the performance of a factory you can’t do it from behind a computer with a few spreadsheets. Our data driven study approach gets us on the floor watching the lines and collecting accurate meaningful data and insights.

That might be start up times, excessive changeovers, poor labour allocation, material shortages or equipment bottlenecks. It might be the way the line is set up and how the parts join together to maintain product flow. Whatever the outputs, we deliver customised solutions and get proper standards of operation in place from which to keep track of efficiency on going.

It would be remiss of me to think the outputs are an opportunity for management to do something different with volumes, run lengths, automation or maintenance. We all know the outputs are about money. More efficiency, less labour, run faster, volume out at all costs.

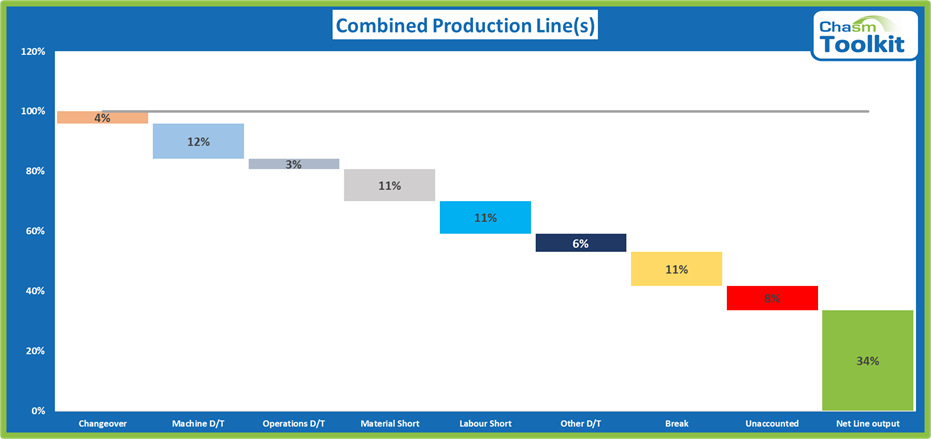

On a recent analysis we undertook a series of performance studies across a number of production lines over a number of days. The chart below shows the collated output of the performance of those lines across a 2-week period. The factory in question had 100 employees whose performance was directly linked to the performance of those production lines.

Most of the categories speak for themselves. Unaccounted loss is a calculated field that shows slow running & minor stoppages.

It’s not a pretty picture but one that is replicated in many manufacturing sites up and down the country. It’s certainly ‘average’ in the sites Chasm see on a daily basis.

So what does it mean in money?

Let’s say for ease of maths the average hourly cost of an employee is £16.00. That’s £31,200 per year per employee. For 100 employees related to these lines that’s an annual labour bill of £3,120,000.

It is expected with accurate costing standards that the labour cost of goods (£3.12m) is recovered in the selling price to customers. In this particular site they use 85% as the standard efficiency for product costings.

Using our 34% nett line efficiency from the chart, the site is losing £1.59m (variance to standard) on just these 100 people alone.

What next for the factory?

Well there are a couple of options, you could reenact the scene from Star Wars where Moff Jerjerrod, when tackled by Darth Vader over his apparent lack of progress, replies “we shall double our efforts”.

Or you could ask for some help from experts who know how to address the process, system & people elements to deliver a sustainable step change in performance.

In this instance the site chose the latter. Coupled with a material saving, implementation of a scheduling solution, factory layout & flow and a great deal of people & competencies we agreed a 30 week project with guaranteed savings of £1.35m at a cost of £270k, thus a 5:1 ROI.